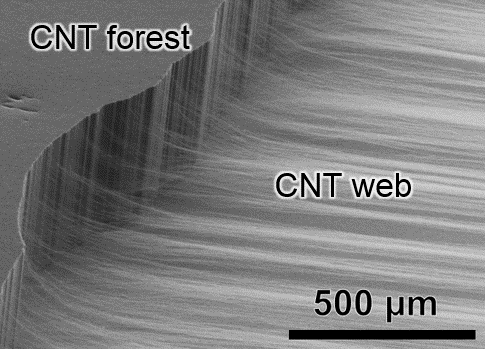

When CNTs grow vertically on a substrate at high density, a dry-spinning phenomenon occurs in which CNTs are connected each other, similar to the case of spinning silk from silkworm cocoons. Since the CNTs are arranged in one direction in a self-organizing manner, the excellent electrical, thermal and mechanical properties of CNTs appear in CNT assemblies, such as spun yarns and sheets. In recent years, this dry CNT spinning technology has attracted attention as an innovative technology that creates new application technologies unique to CNT.

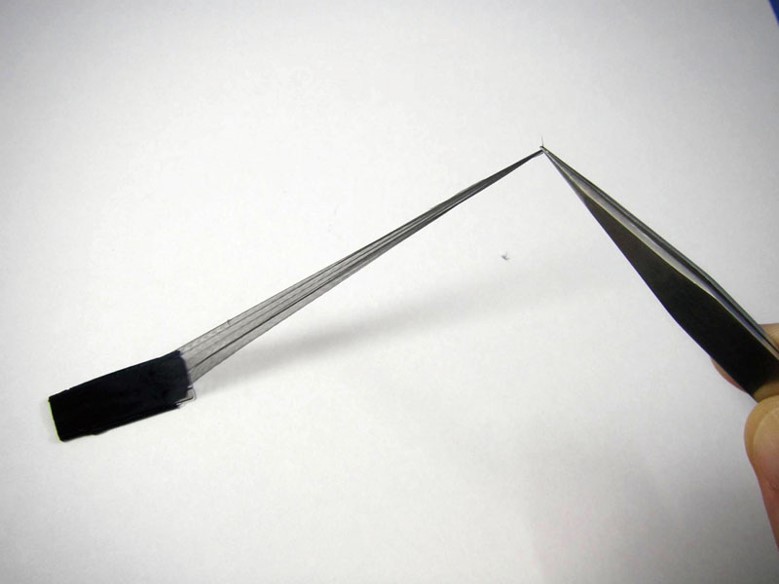

This “CNT spinning” is a phenomenon in which CNTs are successively drawn out in a horizontal direction from a CNT array vertically oriented and grown on a substrate, and is called “dry spinning“. By this process, the CNTs growing three-dimensionally on the substrate are converted into CNT “webs” that form a two-dimensional network. Unlike conventional spinning, CNT webs can be spun without adding twist because the CNTs are bonded together with a strong van der Waals force. Furthermore, sheets can be formed by stacking.

Publication

Study on the mechanical and electrical properties of twisted CNT yarns fabricated from CNTs with various diameters

Yoku Inoue, Kohei Hayashi, Motoyuki Karita, Takayuki Nakano, Yoshinobu Shimamura, Keiichi Shirasu, Go Yamamoto, Toshiyuki Hashida

Carbon 176, 400-410 (2021).

DOI: 10.1016/j.carbon.2021.01.139

One-step grown aligned bulk carbon nanotubes by chloride mediated

chemical vapor deposition

Yoku Inoue, Kazuyuki Kakihata, Yusaku Hirono, Toshinori Horie, Akihiro Ishida, Hidenori Mimura

Applied Physics Letters 92, 213113 (2008).

DOI: 10.1063/1.2937082